DPR construction’s approach to prefabrication

Author: OCRC

Posted on Jan 9, 2025

Category: Off-site Construction

DPR Construction, a general contractor and unique technical builder, is redefining construction through innovative prefabrication methods. Their approach emphasizes efficiency, safety, and quality by integrating prefabricated elements early in the project workflow.

From concept to completion, DPR adopts new technologies and methodologies, effective pre-planning, and collaboration with industry partners to optimize project outcomes.

Streamlined prefabrication workflow

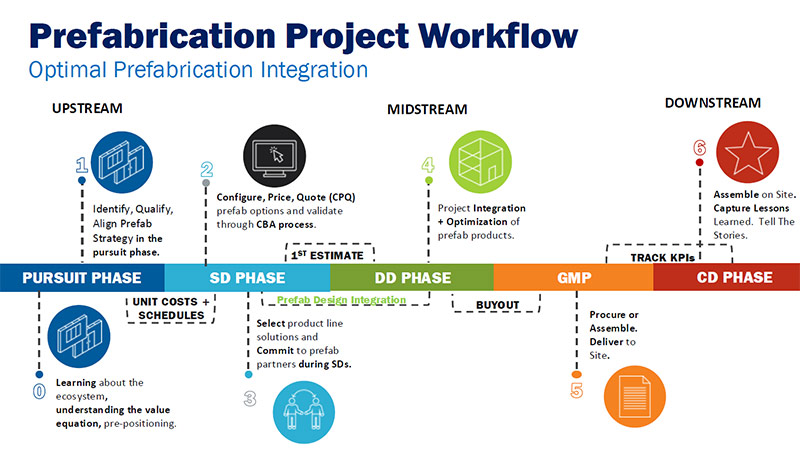

DPR’s process integrates prefabrication at each project phase:

- Pursuit phase: Early alignment of prefabrication strategies with client goals.

- Design phases: Incorporating prefabrication options into configurations, pricing, and finalizing partner commitments.

- Execution: Leveraging preconstruction guides and virtual modeling to ensure seamless delivery.

Advanced prefabricated solutions

DPR employs a variety of prefabrication methods, including, but not limited to:

- Bathroom pods: Fully finished units for rapid on-site installation.

- Volumetric modules: Pre-assembled structures housing essential components.

- Multi-trade racks: Modular assemblies improving efficiency and reducing labor.

- Modular pedestrian bridges: Prefabricated designs minimize road closure durations.

Prefabrication implementation success contributors

DPR Construction has developed a suite of prefabrication project execution documents designed to streamline project workflows and enhance team efficiency.

These resources include guidebooks for critical prefabricated components such as multi-trade racks, modular stairs, exterior wall panels, doors, frames, hardware and headwalls.

The resources are organized into two sections:

- Section A: A comprehensive project line playbook detailing prefabrication methodologies.

- Section B: Appendices featuring KPIs, best practices, project narratives, and lean factory insights.

Expansions are underway to integrate the latest project information and best practices, ensuring these documents remain valuable tools for innovation and performance optimization in prefabrication construction.

Additionally, DPR relies on prefabrication libraries (ie. standard details and models) to establish virtual building of their projects through advanced software such as Revit, Tekla, and Inventor, paired with comprehensive BIM processes, ensuring collaborative workflows.

Prefabrication’s Tangible Benefits

DPR’s initiatives highlight measurable improvements in:

- Cost and schedule efficiency: Achieving cost neutrality or savings while expediting timelines.

- Safety and quality: Controlled environments reduce on-site risks and improve craftsmanship.

- Sustainability: Minimizing waste through precision prefab practices.

Conclusion

DPR’s journey showcases prefabrication as a transformative methodology for construction. Their work emphasizes the importance of early adoption, collaborative strategies, and advanced digital tools. Prefabrication’s integration offers a promising future for streamlined, sustainable, and efficient construction practices.

Did you miss the session live? Check out their presentation recording to learn more about the potential of prefabrication in the construction industry.

Interested in learning more about off-site construction? Join us on the third Thursday of every month for a deep dive into offsite construction with leading experts.

Email offsiteconstruction@unb.ca to be added to the mailing list to be the first to know about these professional development sessions.