Navigating tough terrain: how UNB researchers engage with complexity to reinvent off-road vehicles

Author: Tim Jaques

Posted on Dec 9, 2025

Category: UNB Fredericton

An innovative approach to understand, simulate and design complex systems helps engineers push conventional limits.

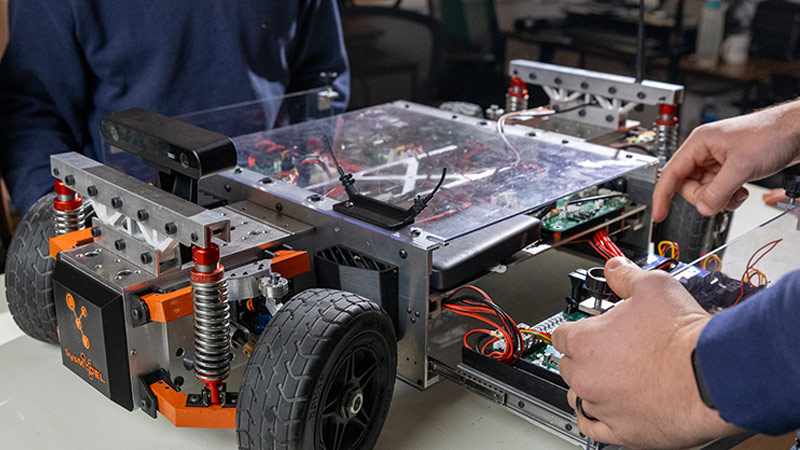

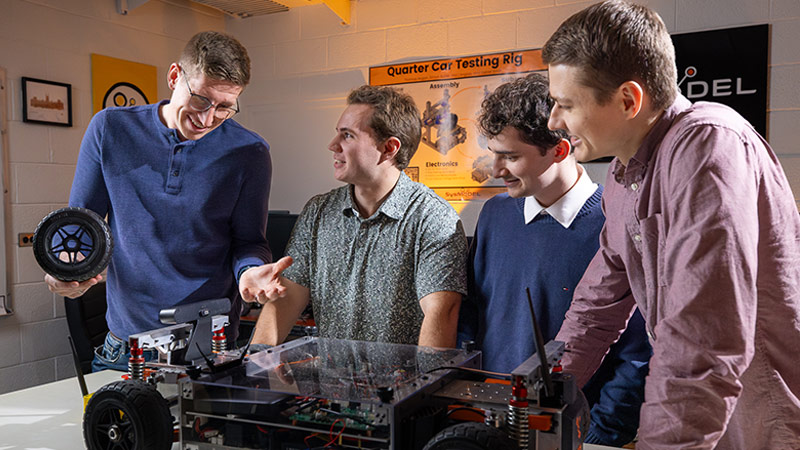

They may look like hobby cars, but two scaled-down electric vehicles in a lab at UNB’s engineering faculty in Sir Edmund Head Hall are doing significant work. These machines test ideas that may reshape how vehicles handle rough terrain.

At the heart of it is the System-Level Model Development Engineering Lab, or Sys-MoDEL, led by Dr. Kush Bubbar, an associate professor in the faculty of engineering.

After a decade in industry working at iconic Canadian tech firms, Bubbar came to UNB and founded the lab to focus on understanding complex systems and to equip students with skills that matter outside the classroom.

“Whatever we build has to be aligned with empowering students to realize their potential and to do important things that can really benefit society,” Bubbar said.

Building models to solve real problems

Sys-MoDEL’s work includes vehicle dynamics and control, marine renewables and mechatronics. “Mechatronics” is a combination of mechanics, electronics and computer technology working together to create intelligent machines and devices.

Bubbar said the lab’s focus is on understanding complex systems through modelling and simulation. That approach has produced two standout projects: Heave-Actuated Research Vehicle (HARV), a one-tenth-scale electric vehicle with independent wheel active suspension, and Multi-Actuated Research Vehicle (MARV), a one-fifth-scale electric vehicle with independent wheel drive and steering.

Jeremy Kimball (BScE'23, D-TME'23), who is pursuing a doctorate in electrical engineering, is behind HARV’s suspension system.

“Traditional suspensions have to make an inherent trade-off choosing between road holding and ride comfort,” he said. “With an active actuator and intelligent controls, you can dynamically change online how that suspension reacts and simultaneously optimize for both road holding and ride comfort.”

An “actuator” in a vehicle is a component that converts an electrical signal into physical motion.

His algorithms use camera systems to scan the road ahead and adjust each wheel in real time. The goal is smooth safe travel even on logging roads or mining sites.

Kimball’s research draws on ideas from rocket control, where changes in mass due to burning fuel alter the dynamics mid-flight because the rocket weighs less the more fuel it burns.

“A lot of these algorithms are derived from the exact algorithms they use in that scenario,” he said.

The system learns as it drives, adapting to payload shifts and terrain changes. That adaptability could simultaneously improve safety and energy efficiency in hard-to-decarbonize sectors.

Actuators for off-road stability

Across the lab, Benjamin DeBoer, currently pursuing a doctorate in electrical engineering, worked on MARV, a vehicle with a drive motor and steering actuator at each wheel.

“We’re removing the old links,” he said, referring to traditional mechanical connections in a vehicle.

“Our goal is to look at how a vehicle reacts when we add more actuators into the mix.”

The design allows maneuvers like crab-walking and turning on the spot, but the real challenge is stability on unpredictable terrain.

“Off-road is especially dangerous and important to New Brunswick because we have large forestry, agriculture, mining and recreational off-road industries,” DeBoer said.

His algorithms are meant to prevent rollovers on slopes and during sudden impacts, while maintaining high performance.

Building MARV meant starting from scratch.

“We looked everywhere and found that if we wanted to do this, we really had to build it ourselves,” Bubbar said.

The platform allows researchers to test control strategies that conventional vehicles can’t support, thanks to electrification and “control-by-wire" systems.

“Control-by-wire systems” replace traditional mechanical or hydraulic linkages with electronic signals, using a computer to interpret driver inputs and send commands to actuators.

Collaborating with Kimball and DeBoer is Caleob Maher-Watson (BScE'25), a research engineer who has helped push both HARV and MARV from lab prototypes to field-ready test vehicles and will begin a master’s degree in electrical engineering with Sys-MoDEL in January.

“When I finished my undergraduate degree, I wanted to continue broadening my skills in embedded systems and control on more intricate mechatronic systems,” he said.

“After joining Sys-MoDEL, I am now refining vehicle hardware and control software as I prepare to tackle my next complex project: developing next-generation motor control algorithms with our industry partner Victory Advanced Technologies.”

Beyond vehicles: energy from waves

Sys-MoDEL’s scope is broader than its research using model cars.

Thomas Hogan (BScE'24), pursuing his master's degree in electrical and computer engineering, is developing a new simulation toolbox for modelling and simulating ocean wave energy converters.

“Wave energy harnesses the motion of ocean waves to extract energy,” he said.

Wave energy offers higher density than wind or solar and complements both, but it’s not yet commercially competitive.

Hogan is building a simulation toolbox in Modelica, an equation-based modelling language for multi-physics systems.

“The novelty compared to some of the other tools is the ability to seamlessly combine different engineering domains into one simulation,” he said.

His work focuses on the full “wave-to-wire” modelling process, meaning from wave absorption to electricity generation. By integrating hydrodynamics with mechanical, hydraulic, and electrical systems, this could help designers optimize performance before running costly experimental tests.

A lab built for complexity

Sys-MoDEL’s mission is to bring clarity to complex systems. Bubbar said that means technical breakthroughs but also preparing students for real-world challenges.

“The focus of the lab was always on how to support students to develop certain skills that enable them to work in these industries, which have high growth potential and a lot of creative opportunities,” he said.

The lab partners with industry to sponsor undergraduate projects, feeding talent into advanced research. Its work on electrification, control systems and renewable energy reflects a broader push toward sustainability.

For Bubbar, the appeal is in tackling complex problems.

“We don’t really like to do standard work. We want the tough stuff.”