Expertise and ingenuity at UNB limb clinic go hand-in-hand to change lives

Author: Jeremy Elder-Jubelin and Roseleen Kafley

Posted on Jul 5, 2023

Category: UNB Saint John , UNB Fredericton

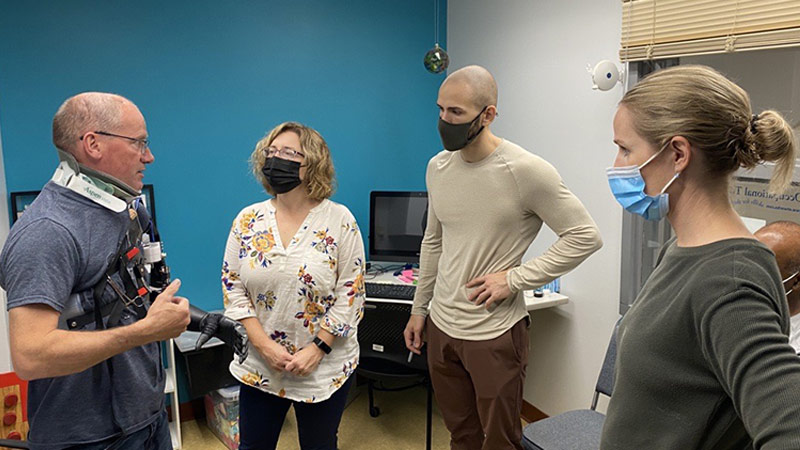

Left to right: Troy Chapman; Wendy Hill, research occupational therapist; Dan Dafonseca, prosthetics research technician; Heather Daley, research prosthetist. Photo credit: Jeremy Elder-Jubelin.

Near the bottom of the University of New Brunswick’s (UNB) Fredericton campus is a small clinic that changes peoples' lives, one prosthesis at a time.

Sometimes, a client has a specific request that gives the Atlantic Clinic for Upper Limb Prosthetics pause – like their recent project for Troy Chapman. Chapman had a straightforward request; he wanted to be able to detach and reattach his prosthetic arm, without having to remove the socket and harness.

There was, however, one small problem: As far as the team could find, there were no existing products or solutions for the kind of single-hand, shoulder-level detachment mechanism he needed. For this team, though ‘impossible’ is a challenge, not an answer – and Chapman would get the arm he was looking for.

The Atlantic Clinic for Upper Limb Prosthetics is part of UNB’s Institute for Biomedical Engineering and supports the community by combining technical expertise with access to leading-edge research. It specializes in helping individuals who need artificial upper limbs or other devices to help with an upper limb difference or complex upper limb dysfunction.

Removable artificial limbs are especially helpful for individuals with neck injuries, like Chapman, as they can increase comfort and reduce strain by removing or adjusting the weight on their upper body when needed, making it easier to wear all day.

For Dan Dafonseca, a prosthetics research technician, Heather Daley, a research prosthetist, and Wendy Hill, a research occupational therapist – the team that took on Chapman’s request – they would need to tap into that expertise and innovative thinking to bring it to life.

Troy’s existing prosthesis was detachable – not because of its original design and construction, but instead because of Troy’s ingenuity and needs. When he received his first prosthesis at a different clinic, he was told a detachable one wouldn’t be possible. So, he took it home to his workshop and modified it himself, using a seatbelt buckle to enable the limb to be removed.

As they do with most projects, this multidisciplinary team worked collaboratively, each bringing unique expertise to the table. Together, they would make sure that the limb did what Troy needed it to, that it was functional, and that it fit well and minimized pain and physical stress.

To provide Troy with the functionality he sought, the team would have to create an attachment mechanism from scratch. It would need to incorporate the electronic pass-throughs that would allow Troy to control the arm, as well as needing to physically secure the arm, so that it could be removed and reconnected with the fewest steps.

The team drafted designs for a connector that would sit between the shoulder joint and the elbow joint – essentially, as part of the upper arm – that contained the electronic passthrough and locking mechanisms, and that would prevent the arm from unwanted rotation around the central pin.

The arm uses a pin locking mechanism – an off-the-shelf component generally used to attach a lower limb prosthesis – to securely attach the arm to the shoulder mount. The electronic connection is enabled using a spring-loaded pin connector -- like the “MagSafe” connector used to plug in a MacBook. By integrating the electronic and physical connection mechanisms into a single sliding movement, this unique design makes it easier to attach or remove the limb.

The arm itself was also custom designed to house the arm’s components, and was 3D printed on-site in carbon fiber nylon and then reinforced with a carbon fiber lamination, one of the lightest and strongest materials available.

Photo caption: Wendy Hill (L) and Heather Daley (R), with Troy’s new prosthetic’s shoulder mount (front) and his previous one (back).

Once they had a finalized design solution, the team fabricated three different arms to fit the shoulder mount: a full-length powered arm with an elbow joint, a shorter powered arm, without an elbow, for close-up tasks, and a lighter, passive arm. Like the overall design itself, these components were selected and designed based on Troy’s needs and goals rather than on existing or standardized solutions.

The team recently completed the final fit adjustments, sending Troy home with a new prosthesis ready to live and work – no seatbelt required.