Combining Mechanics, Coding and Entrepreneurship to Grow an Innovative Business That’s Taking the Aerospace Industry by Storm

Author: Engineering Alumni Office

Posted on Sep 6, 2018

Category: Alumni Spotlight

Shaun Kennedy (BScME’07) says he was always an inventor. In high school in Cape Breton, he came up with a new model for a Zamboni and even started the patent process. In the early 2000’s, taking Computer Science at Acadia seemed like a smart move, but his heart wasn’t into it. Still, he finished his degree and then began an Engineering degree, transferring to UNB to the mechanical stream.

It was a good move, as he was able to pick up skills from both degrees like coding and design that would become extremely useful in his career. Shaun liked mechanical engineering so much he that worked two summers during his studies with Professor Rickey Dubay on building control systems for injection molding machines. He found he loved combining electronics and mechanics and became adept at writing code for control systems.

After graduating, he took a job with Atomic Energy of Canada in Ontario, where he designed components for a robot that refuels nuclear reactors. It was a fantastic first job out of university, but after three years he was about to start a family with his wife and they yearned to be closer to home.

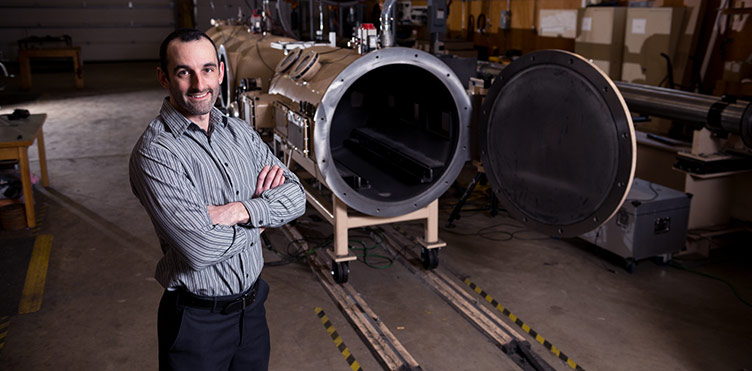

Enter the UNB High-Speed Impact Facility. Shaun’s background doing both coding and simulations allowed him to jump into doing high-impact research and testing for defense, aerospace and space applications. During the seven years he worked at the lab, he developed expertise in testing subsonic, supersonic and hypervelocity impacts. He also continued his studies at UNB part-time, working on a Masters in Mechanical Engineering, eventually skipping right into working toward a PhD (which he’s now about to complete).

Shaun began getting traction in using non-contact optical 3D measurement techniques to measure coordinates, displacements, strains, velocities and accelerations of objects hitting different materials at high speeds. These optical techniques are a new way of testing materials that is more beneficial than traditional testing methods such as a strain gauge. It can measure much larger strains and give full-field measurements through a 3D contour plot of data, so clients get hundreds of thousands of data points, instead of just one single point being tested.

He saw an opportunity in industry: this new technology and technique offered companies better data at a fraction of the cost since testing was much less time-intensive than the current methods. In 2016 he broke out on his own to form the startup company Mach85 and serve some of the largest aerospace companies in the world. They were blown away by the technology, which is one of a kind in Canada and competes with only a handful of others around the world.

Mach85 offers companies non-contact 3D measurements so that they can get the whole picture of how their materials (used in airplanes, missiles, tanks, spacecraft, bridges and even hockey sticks and golf clubs) stand up to high-speed impacts, static loads, fatigue, vibrations, etc.

Aside from the 3D measurements, Mach85 also uses non-linear explicit dynamic finite element analysis, to accurately simulate everything from quasi-static testing to hypervelocity impacts, as well as static structural analyses and explosives.

Shaun hit the road to sell his new services at aerospace and defense conferences, but soon, companies began knocking on his door, and he was able to hire an Engineering Specialist and expand the company. Several of the largest aerospace companies in the world, as well as local firms, are now contracting him to test their products using their non-contact 3D measurement techniques. They’re saving money and getting better results than in the past.

Recently, Shaun and Mach85 got another boost when UNB came calling to ask him to manage, expand and promote the newly named Ballistics and Mechanical Test Lab. The full Mach85 team now manages the lab and brings in new contracts, in addition to their own clients. They (as well as UNB co-op students and a lab employee) are able to utilize the subsonic, supersonic, hypervelocity and hail ‘guns’ in the lab to evaluate the impact-resistant performance of materials when projectiles are launched at them. And UNB is able to use the company’s 3D measurement capabilities that will allow them to bring in a new revenue stream of clients. It’s a win-win situation.

And it’s a dream come true for Shaun. “UNB really has something special here with this lab,” he excitedly says. “It’s a centre of excellence for aerospace testing that’s a game changer for Canada and the whole industry. We can test for hail, environmental effects, pressure, altitude, vibrations and temperature and use the 3D measurement technique to provide superior data. Aerospace and defense companies can spend their money right here in Canada for testing rather than go to the U.S. or Europe.”

Shaun is jumping into his entrepreneurial venture and the UNB Ballistics and Mechanical Test Lab with both feet. “To be in Atlantic Canada doing this kind of ground-breaking work in a lab that’s uniquely designed for the work I love…I couldn’t ask for more.”